Newsroom

The production of hydrogen from biomass has garnered increasing attention, with thermochemical methods emerging as the most widely adopted approach. Among these, steam gasification stands out as a particularly promising technique for producing H2-rich syngas. However, a major challenge associated with the gasification process is the formation of tar, which can cause equipment corrosion and pipeline blockages, significantly compromising the overall efficiency of the process.

The addition of catalysts during gasification has proven effective in cracking tar and enhancing hydrogen production. Moreover, inorganic minerals found in biomass, such as alkali and alkaline earth metals (AAEMs), have been observed to promote the production of H2-rich syngas. However, further research is required to clarify how AAEMs impact gas production and the mechanisms behind the interactions among different metals.

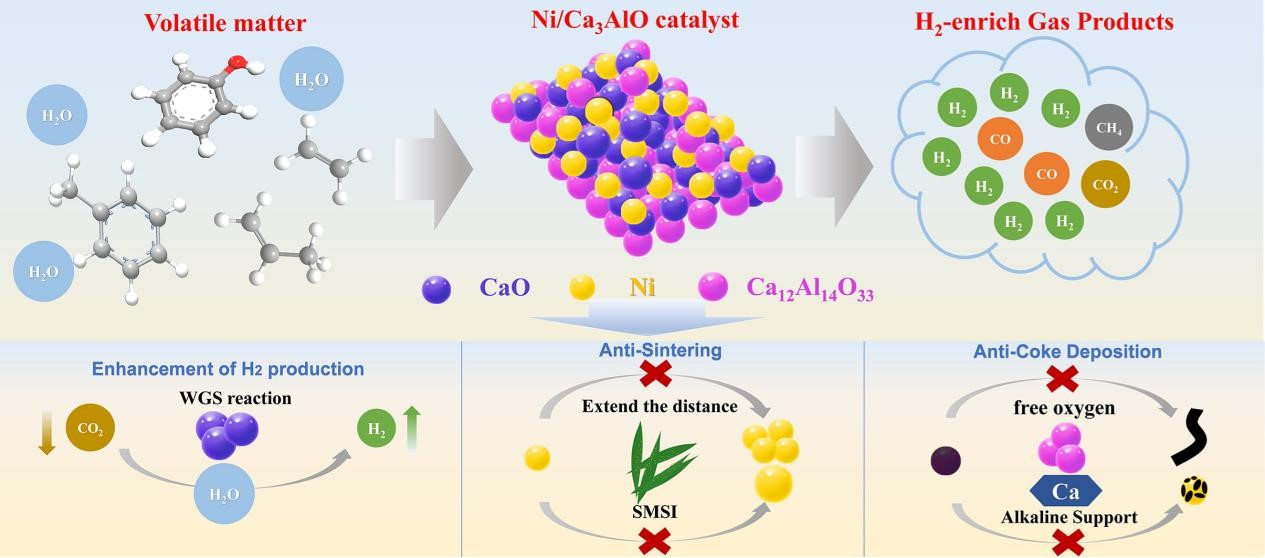

To tackle these challenges, a research team led by Prof. YIN Jiao from the Xinjiang Technical Institute of Physics and Chemistry of the Chinese Academy of Sciences has developed a series of Ni/CaO-Ca12Al14O33 catalysts. The team has made significant progress in improving the stability of these catalysts.

Experimental results indicated that the Ni/Ca3AlO catalyst demonstrated excellent catalytic performance and cyclic stability. The yield and concentration of hydrogen in the syngas were measured at 30.08 mmol/gbiomass and 60.61 vol% during the initial reaction. Notably, minimal carbon deposition and slight sintering were observed on the catalyst surface after ten cycles.

The catalyst's remarkable anti-sintering performance was mainly attributed to its unique blade-like morphology, which effectively enhanced metal-carrier interactions, thereby preventing Ostwald ripening. Furthermore, the inhibition of filamentary carbon formation by Ca12Al14O33 in the carriers and the suppression of encapsulated carbon precursors through calcium doping contributed to the catalyst’s resistance to carbon accumulation.

This research, published in the journal Energy, provides a theoretical foundation for the design of novel nickel-based catalysts and their application in hydrogen production from biomass catalytic gasification.

Fig. 1 Foliated Ni/Ca3AlO catalysts are used for biomass gasification to achieve high stability hydrogen production. (Image by YIN Jiao)